iPET Injection Molding Machine

Product Description

Product Overview

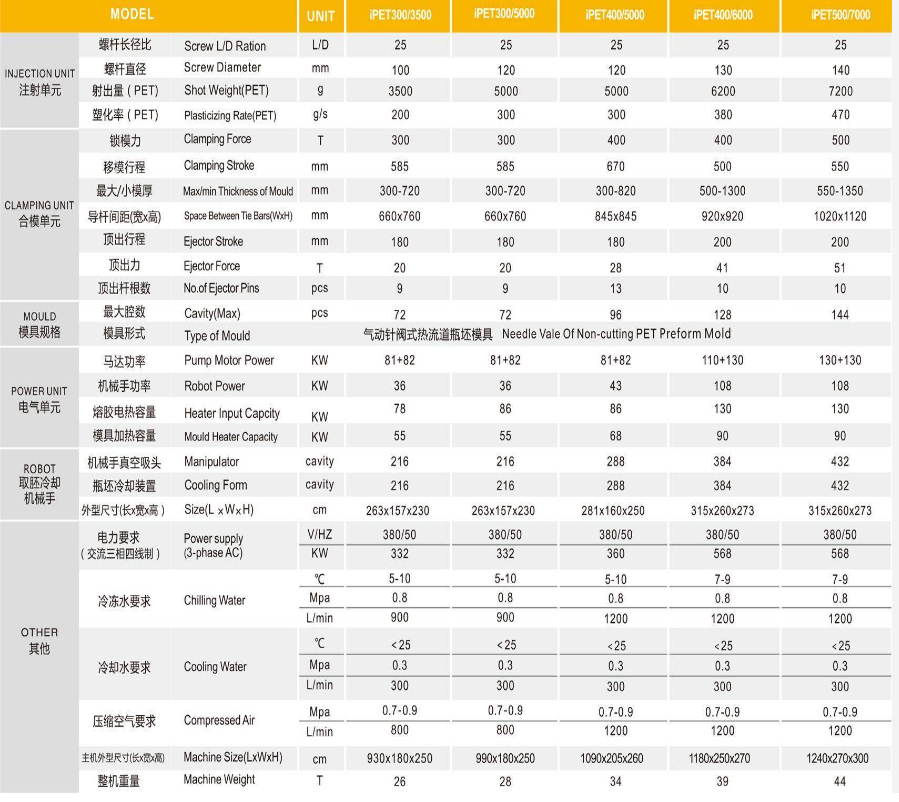

Screw Diameter: 100mm Distance between Tie Bars: 660*760mm Shot Weight (g): 3500 Plasticizing Rate(PET): 200g Ejector Stroke(mm): 180 Max Cavities: 72-144 Clamping Force : 300T Machine Size(LxWxH):9.3x1.8x2.5m Machine Weight: 26 Ton

HIGH WORLD CLASS HIGH PERFORMANCE PREFORM PRODUCTION SYSTEM

♦ Produce with the preform injection molds up to 144 cavities

♦ Double screw design

iPET Injection Molding Machine Feature:

1. Independent electric screw drive brings you both melting and energy efficiency

2. BECKHOFF centralized control system special designed for PET production.

3. Three station post cooling robot makes the preform perfectly cooled with better cycle time.

4. Advanced servo valve control technology makes the highly dynamic injection possible.

5. Up to 5 sets of high efficient accumulator ensure the stability of high capacity injection .

6. Synchronous material melting,plasticization and injection at the same.

7 Special design for PET preform mould,which ensure the fast clamping movemen

FEATURES AT A GLANCE

iPET Injection Molding Machine allows you gain the same level of specification as European machine but with lower investment cost at the same time. The injection machine can produce with the preform injection molds up to 144 cavities which including double screw design High Speed Injection Machine precision preform injection molds, post cooling, take out robot, centralized control system and high efficient material drying system. The results are higher production efficiency, and better preform quality. You can also choose MHT preform injection molds from Germany at the same time.

Demark also insist on the "turnkey" solution concept by offering preform design and whole plant planning to our customers with more suggestion on various aspects to help our customers keep long term competitive strength in the hyper competitive, changeful consuming market.

PRODUCT SPECIFICATIONS

SALES AND SERVICE NETWORK

Tincoo(Changxing) Packaging Technology Co.,Ltd

TINCOO MACHINERY is a professional supplier devoted to the designing & production of big-scaled and multi-layer extrusion molding machine. The company is located on the south shore of Taihu Lake--Huzhou, with total investment of 10 million dollars, covering a total area of 58,000 square meters. Machines from the company are mainly for export, and have been exported to more than 100 countries in Asia, Mid-East, Europe, Africa, Australia, and Latin-America. The marketing network has covered all over the world.

There are 2 general departments in our company: machinery department & mold department. Machinery department focuses on designing and developing various plastic extrusion blows molding machine by learning foreign advanced techniques& administration faith; mold department focuses on mould design and manufacturing of preform mold& extrusion mold&blow mold. According to different character of different plastic material, we have successfully designed different machines, which are suitable for different products: container of PE, PVC, PP, PC, PETG, PS, PAN, PA, PPE, PPO, ABS, POM, TRA, etc(like big tank, collapsible container car plastic hollow part, office equipment,sport facility, toys, mechanical container,5 gallon PC container,tool box, etc). We have an experienced team will design, produce and offer service after service with great team spirit.High quality but reasonable price has been widely approved by our customers from local and abroad.

There are 2 general departments in our company: machinery department & mold department. Machinery department focuses on designing and developing various plastic extrusion blows molding machine by learning foreign advanced techniques& administration faith; mold department focuses on mould design and manufacturing of preform mold& extrusion mold&blow mold. According to different character of different plastic material, we have successfully designed different machines, which are suitable for different products: container of PE, PVC, PP, PC, PETG, PS, PAN, PA, PPE, PPO, ABS, POM, TRA, etc(like big tank, collapsible container car plastic hollow part, office equipment,sport facility, toys, mechanical container,5 gallon PC container,tool box, etc). We have an experienced team will design, produce and offer service after service with great team spirit.High quality but reasonable price has been widely approved by our customers from local and abroad.

Product Categories : Injection Molding Machine

Premium Related Products

Other Products

Hot Products

170ton High Synchronized Injection Molding Machine100 Ton Bakelite Injection Molding Machine with Servo Motor70 Ton Bakelite Injection Molding Machine170 Ton Energy Saving Plastic Injection Molding Machine100ton Horizontal Standard Injection Moulding MachineTwo Colors Automatic Injection Moulding Machine for Hand ShankHK 500t Energy Saving Injection Molding MachineXw128t Servo Motor Plastic Injection Molding Machine PriceHt-30 Vertical Hydraulic Injection Molding Machine for PlugHl-125g Vertical Injection Molding Machine with Servo ControlHl-300g Vertical Injection Molding Machinery for Shoe Sole1100 Ton Plastic Injection Molding Machine Price with High SpeedHigh Speed Injection Molding Plastic Machine (wmk-400)500 Ton Plastic Injection Machine (WMK-530)400t Pet Preform Energy Saving Plastic Injection Molding Machine (WMK-400)170 Ton Plastic Injection Molding Machine