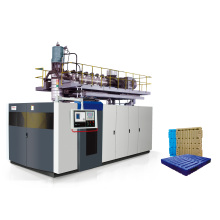

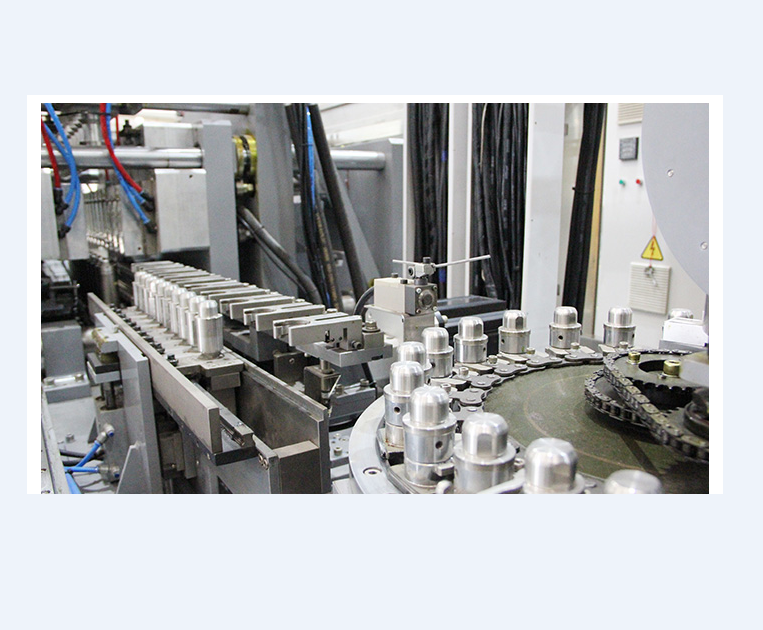

SFL-PP Series PET Blow Molding Machine

Product Description

Product Overview

♦ High performance-price ratio ,high stability for multi serve applications

♦ Simplicity to install,use and maintain("plug and blow" concept)

♦ Significant savings due to competitive pricing

♦ High production

1. Linear two servo motors and double hinges replace the original tie bar clamping,which brings simpler structure,smaller size and less weight and make the machine run smoother,reduce shock and improve speed .

2. New design of steel ball torque limiter efficiently protect the related parts of blowing machine and automatically find the position of itself which reduces the difficulty of maintenance so that maintainer could solve fault easier .

♦ Low energy consumption

1. Without enlarging thePET Blow Molding Machine size ,the heating system is consist of stereoscopic and reduce unit energy consumption.

2. With a closed type dust-proof air inlet hood and an independently air filter inlet system on the equipment, is good for

compensating the exhausting air so no need collect air from purification work shop thereby saving energy consumption . The exhaust system in the blowing machine adopts the independent control ,which does not affect the environment of the workshop and has a higher degree of cleanliness. It minimizes the external pollution to the blower .

(high efficiency filtration and purification system FFU,fan ,wind pipe are provided by users).

♦ Quality bottle

1. Adopting integrated technology of blowing-welding as one ,the structure is more simple and reliable.

2. Getting rid of particles powerfully at the same time loading performs and welding rings by using a high-performance static eliminator .

♦ Simplicity to install,use and maintain("plug and blow" concept)

♦ Significant savings due to competitive pricing

♦ High production

1. Linear two servo motors and double hinges replace the original tie bar clamping,which brings simpler structure,smaller size and less weight and make the machine run smoother,reduce shock and improve speed .

2. New design of steel ball torque limiter efficiently protect the related parts of blowing machine and automatically find the position of itself which reduces the difficulty of maintenance so that maintainer could solve fault easier .

♦ Low energy consumption

1. Without enlarging thePET Blow Molding Machine size ,the heating system is consist of stereoscopic and reduce unit energy consumption.

2. With a closed type dust-proof air inlet hood and an independently air filter inlet system on the equipment, is good for

compensating the exhausting air so no need collect air from purification work shop thereby saving energy consumption . The exhaust system in the blowing machine adopts the independent control ,which does not affect the environment of the workshop and has a higher degree of cleanliness. It minimizes the external pollution to the blower .

(high efficiency filtration and purification system FFU,fan ,wind pipe are provided by users).

♦ Quality bottle

1. Adopting integrated technology of blowing-welding as one ,the structure is more simple and reliable.

2. Getting rid of particles powerfully at the same time loading performs and welding rings by using a high-performance static eliminator .

FEATURES AT A GLANCE

1. No functions are duplicated, auxiliary functions are eliminated ,the machine is stripped of complex parts and it boasts a

smaller footprint. The oven, transfer and blowing units all have independent drives. This offers the flexibility to adjust blowing time.

2. Time savings and security as the DMK-L is a fast reliable machine using high technology shared with the DMK-R range .

3. Flexibility and choice owing to its wide scope of bottle dimensions and to its quick change system .

4. The advantages of innovative technology such as pitch change during transfer or a cam system to command the mold unit.

Linear two servo motors and double hinges replace the original tie bar clamping which brings simpler structure, smaller size and less weight and make the machine run smoother, reduce shock and improve speed.

New design of Steel ball torque limiter efficiently protect the related parts of blowing machine and automatically find the

position of itself which reduces the difficulty of maintenance so that maintainer could slove fault easier.

All servo motors are imported from OMRON Japan, which are controlled by net that keeps them stable and reliable.

Without enlarging the blowing machine size, the heating system is consist of stereoscopic and multilayer heating lamps which improves the machine capacity to 13,000BPH for 250ML bottles and reduce unit energy consumption.

With a closed type dust-proof air inlet hood and an independently air filter inlet system on the equipment, is good for

compensating the exhausting air so no need collect air from purification work shop thereby saving energy consumption. The exhaust system in the blowing machine adopts the independent control, which does not affect the environment of the workshop and has a higher degree of cleanliness. It minimizes the external pollution to the blower. (high efficiency filtration and purification system FFU, fan, wind pipe users-owned).

Adopting integrated technology of blowing-welding as one, the structure is more simple and reliable.

Getting rid of particles powerfully at the same time loading preforms and welding rings by using a high-performance static

eliminator.

smaller footprint. The oven, transfer and blowing units all have independent drives. This offers the flexibility to adjust blowing time.

2. Time savings and security as the DMK-L is a fast reliable machine using high technology shared with the DMK-R range .

3. Flexibility and choice owing to its wide scope of bottle dimensions and to its quick change system .

4. The advantages of innovative technology such as pitch change during transfer or a cam system to command the mold unit.

Linear two servo motors and double hinges replace the original tie bar clamping which brings simpler structure, smaller size and less weight and make the machine run smoother, reduce shock and improve speed.

New design of Steel ball torque limiter efficiently protect the related parts of blowing machine and automatically find the

position of itself which reduces the difficulty of maintenance so that maintainer could slove fault easier.

All servo motors are imported from OMRON Japan, which are controlled by net that keeps them stable and reliable.

Without enlarging the blowing machine size, the heating system is consist of stereoscopic and multilayer heating lamps which improves the machine capacity to 13,000BPH for 250ML bottles and reduce unit energy consumption.

With a closed type dust-proof air inlet hood and an independently air filter inlet system on the equipment, is good for

compensating the exhausting air so no need collect air from purification work shop thereby saving energy consumption. The exhaust system in the blowing machine adopts the independent control, which does not affect the environment of the workshop and has a higher degree of cleanliness. It minimizes the external pollution to the blower. (high efficiency filtration and purification system FFU, fan, wind pipe users-owned).

Adopting integrated technology of blowing-welding as one, the structure is more simple and reliable.

Getting rid of particles powerfully at the same time loading preforms and welding rings by using a high-performance static

eliminator.

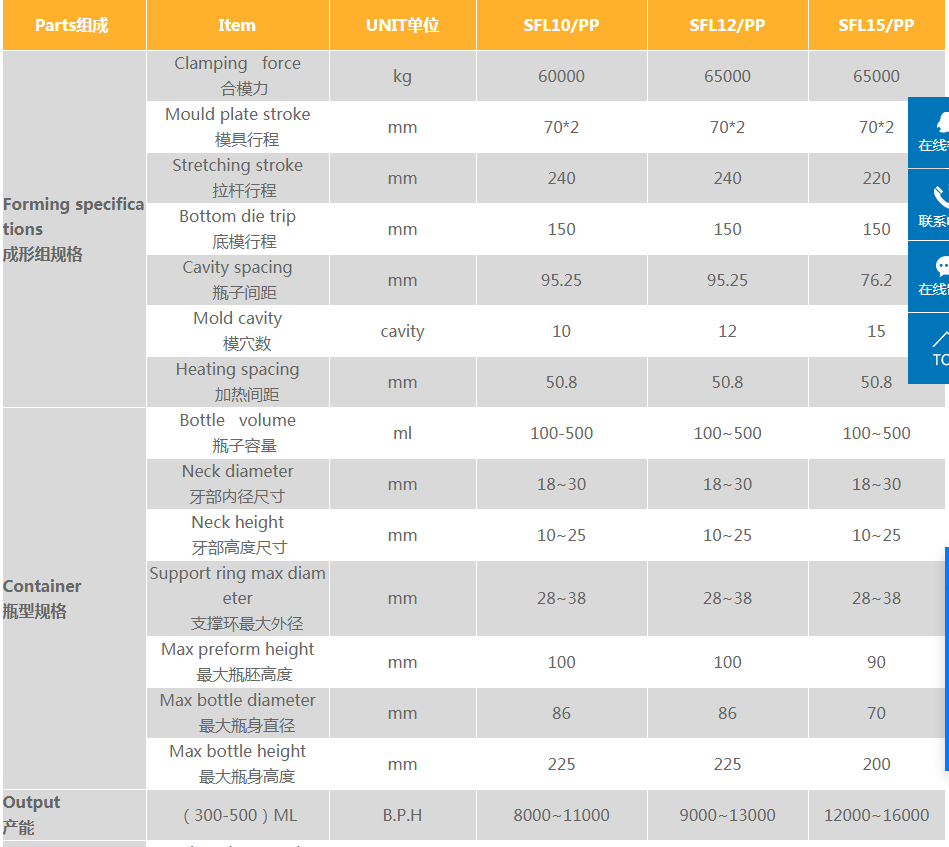

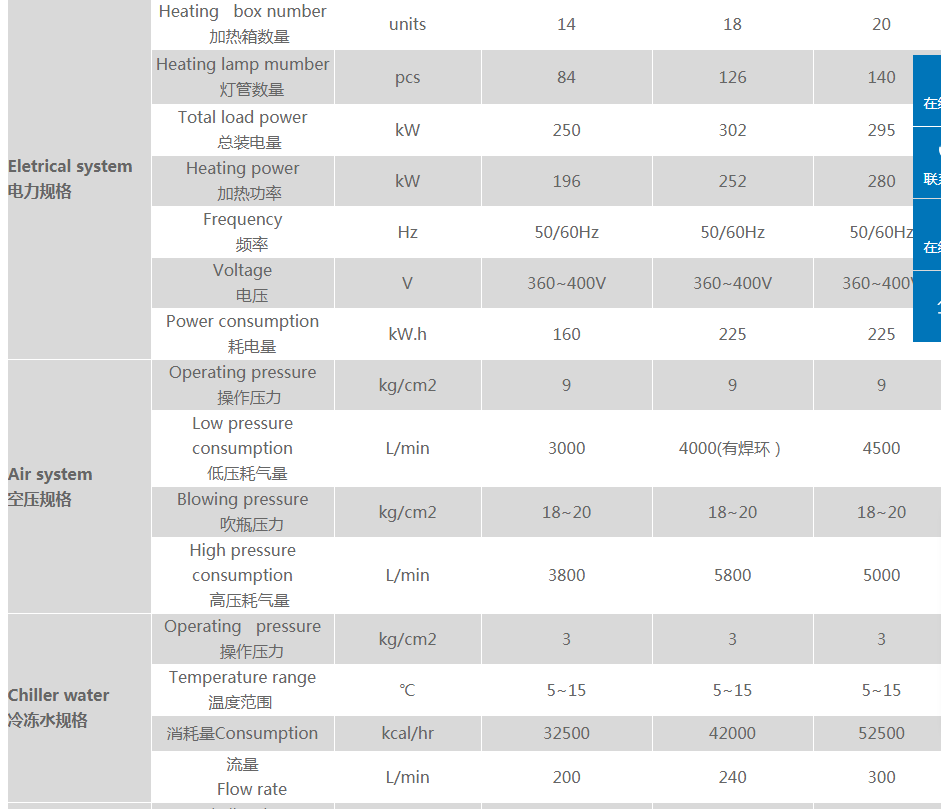

PRODUCT SPECIFICATIONS

Product Categories : PET Blow Molding Machine

Premium Related Products

Other Products

Hot Products

170ton High Synchronized Injection Molding Machine100 Ton Bakelite Injection Molding Machine with Servo Motor70 Ton Bakelite Injection Molding Machine170 Ton Energy Saving Plastic Injection Molding Machine100ton Horizontal Standard Injection Moulding MachineTwo Colors Automatic Injection Moulding Machine for Hand ShankHK 500t Energy Saving Injection Molding MachineXw128t Servo Motor Plastic Injection Molding Machine PriceHt-30 Vertical Hydraulic Injection Molding Machine for PlugHl-125g Vertical Injection Molding Machine with Servo ControlHl-300g Vertical Injection Molding Machinery for Shoe Sole1100 Ton Plastic Injection Molding Machine Price with High SpeedHigh Speed Injection Molding Plastic Machine (wmk-400)500 Ton Plastic Injection Machine (WMK-530)400t Pet Preform Energy Saving Plastic Injection Molding Machine (WMK-400)170 Ton Plastic Injection Molding Machine