Basic Info

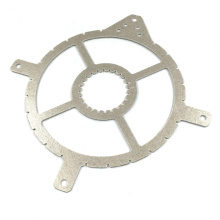

Model No.: FT-ZS-01

Click on the follow link to find out more information: https://www.feetoolighter.com/lighter-automatic-flame-size-adjustment-machine/

Company Info

- Company Name: GuangDong Feituo Automation Technology Co., Ltd.

- Representative: Ya Wenhuan

- Product/Service: Ultrasonic Welding Machine , Meter Valve Assembly Machine , Lighter Automatic Inflation Equipment , Automatic Production Line , Fully Automatic Inspection Machine , Labeling Machine

- Capital (Million US $): ten million RMB

- Year Established: 2017

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 61% - 70%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 4

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: Fewer than 5 People

- OEM Services Provided: NO

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Room 223,No.107,Zhufoling Road,Tangxia Town,Dongguan City,Guangdong Province

- Contact Person: Mr. 黄

- Tel: 86-15675907557

Premium Related Products

Other Products

Hot Products

170ton High Synchronized Injection Molding Machine100 Ton Bakelite Injection Molding Machine with Servo Motor70 Ton Bakelite Injection Molding Machine170 Ton Energy Saving Plastic Injection Molding Machine100ton Horizontal Standard Injection Moulding MachineTwo Colors Automatic Injection Moulding Machine for Hand ShankHK 500t Energy Saving Injection Molding MachineXw128t Servo Motor Plastic Injection Molding Machine PriceHt-30 Vertical Hydraulic Injection Molding Machine for PlugHl-125g Vertical Injection Molding Machine with Servo ControlHl-300g Vertical Injection Molding Machinery for Shoe Sole1100 Ton Plastic Injection Molding Machine Price with High SpeedHigh Speed Injection Molding Plastic Machine (wmk-400)500 Ton Plastic Injection Machine (WMK-530)400t Pet Preform Energy Saving Plastic Injection Molding Machine (WMK-400)170 Ton Plastic Injection Molding Machine