DHD-5L Blow Molding Machine--1 Diehead Double Work Stations

Product Description

Product Overview

DHD-5L Blow Molding Machine

* Introducing advanced technology from Germany, Italy, japan etc.Involving advanced design and production of super large-scale blow-molding machine and engineering management capability. Holding over 40 items Patent Technologies.

*Special design can be made to order to for visistipe(VS) or two colors(TC) or two layers(TL) bottles.

DHD-5L Blow Molding Machine General Introduction

1. DHD-5L blow molding machine is a double station machine, and suitable for producing high quality container with medium output with from one to six fold die head, for use in the packaging of petroleum, cosmetics, chemicals, pharmaceuticals, food, toys and auto-parts.

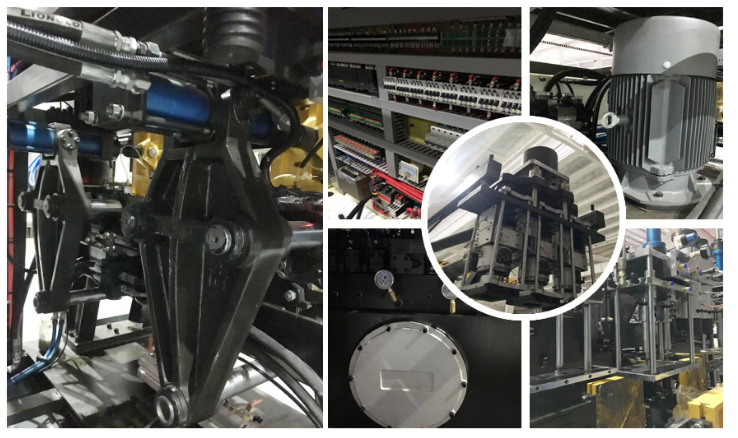

2. The clamping system is a high-precision single-station linear guide, extrusion system using a hard gear reducer and inverter imported from Japan.

3. The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve.

4. The control system consists of PLC and Human-machine interface imported from Japan, an automatic temperature control module and imported electrical part.

DHD-5L Blow Molding Machine Basic Components

1. Die: Vertical first-in first-out structure

2. Extruder unit: Imported automatic temperature control module, with the screw driven by converter electrical machine and hard gear surface reducer to achieve infinite speed variation.

3. Clamping unit: Hydraulic fixed bi-directional clamping system with good stability.

4. Hydraulic system: Imported hydraulic unit and proportional control.

5. Electrical system: Siemens PLC, world brand, electrical components

* Introducing advanced technology from Germany, Italy, japan etc.Involving advanced design and production of super large-scale blow-molding machine and engineering management capability. Holding over 40 items Patent Technologies.

*Special design can be made to order to for visistipe(VS) or two colors(TC) or two layers(TL) bottles.

DHD-5L Blow Molding Machine General Introduction

1. DHD-5L blow molding machine is a double station machine, and suitable for producing high quality container with medium output with from one to six fold die head, for use in the packaging of petroleum, cosmetics, chemicals, pharmaceuticals, food, toys and auto-parts.

2. The clamping system is a high-precision single-station linear guide, extrusion system using a hard gear reducer and inverter imported from Japan.

3. The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve.

4. The control system consists of PLC and Human-machine interface imported from Japan, an automatic temperature control module and imported electrical part.

DHD-5L Blow Molding Machine Basic Components

1. Die: Vertical first-in first-out structure

2. Extruder unit: Imported automatic temperature control module, with the screw driven by converter electrical machine and hard gear surface reducer to achieve infinite speed variation.

3. Clamping unit: Hydraulic fixed bi-directional clamping system with good stability.

4. Hydraulic system: Imported hydraulic unit and proportional control.

5. Electrical system: Siemens PLC, world brand, electrical components

FEATURES AT A GLANCE

Advanced processing equipment:

1. Introducing advanced technology from Germany, Italy, Japan etc.

2. Involving advanced design and production of super large-scale blow-molding machine and engineering management capability.

3. Holding over 40 items Patent Technologies.

DHD-5L Blow Molding Machine Advantages

1. Machine platen can be moved down & up.

2. Machine platen has been strengthened.

3. All tubes and lines are located in good order.

4. Mold-moving stand is in box shape. It can make movement more stable and avoid distortion.

5. Tie bars are strengthened to make movement more stable

6. Mold-closing and mold-moving cylinder has been equipped with joint bearing. It can help protect mold-closing and mold-moving cylinder.

7. New blow construction. It can blow vertically and even blow from certain angle.

8. Blow construction has connected to exhausting air pipe. It can make product cool down more quickly.

9. Machine is with auto deflashing.

10. Machine can be connected to conveyor to carry the slitter edge to crusher to be reused.

11. Machine can be connected to conveyor to carry out bottle and connects the filling machine directly.

12. Machine can be equipped with robot arm to take out the bottle.

13. Machine can be equipped with circle-type cutter to trimmer the bottle with foil-sealing type.

14. Mold platen has been professionally designed in construction and shape to keep stable.

15. New and safe machine door.

16. Machine is equipped with reduction valve in the mold-moving parts. It can make mold move more quickly and more stably.

17. Machine is equipped with manual adjuster to adjust the position of mold and blow pin. It makes the adjustment more

conveniently.

18. Screw stand is of high rigidity.

19. Screw can be adjusted forward and backward, leftward and rightward.

1. Introducing advanced technology from Germany, Italy, Japan etc.

2. Involving advanced design and production of super large-scale blow-molding machine and engineering management capability.

3. Holding over 40 items Patent Technologies.

DHD-5L Blow Molding Machine Advantages

1. Machine platen can be moved down & up.

2. Machine platen has been strengthened.

3. All tubes and lines are located in good order.

4. Mold-moving stand is in box shape. It can make movement more stable and avoid distortion.

5. Tie bars are strengthened to make movement more stable

6. Mold-closing and mold-moving cylinder has been equipped with joint bearing. It can help protect mold-closing and mold-moving cylinder.

7. New blow construction. It can blow vertically and even blow from certain angle.

8. Blow construction has connected to exhausting air pipe. It can make product cool down more quickly.

9. Machine is with auto deflashing.

10. Machine can be connected to conveyor to carry the slitter edge to crusher to be reused.

11. Machine can be connected to conveyor to carry out bottle and connects the filling machine directly.

12. Machine can be equipped with robot arm to take out the bottle.

13. Machine can be equipped with circle-type cutter to trimmer the bottle with foil-sealing type.

14. Mold platen has been professionally designed in construction and shape to keep stable.

15. New and safe machine door.

16. Machine is equipped with reduction valve in the mold-moving parts. It can make mold move more quickly and more stably.

17. Machine is equipped with manual adjuster to adjust the position of mold and blow pin. It makes the adjustment more

conveniently.

18. Screw stand is of high rigidity.

19. Screw can be adjusted forward and backward, leftward and rightward.

PRODUCT SPECIFICATIONS

SALES AND SERVICE NETWORK

Product Categories : Blow Molding Machine

Premium Related Products

Other Products

Hot Products

170ton High Synchronized Injection Molding Machine100 Ton Bakelite Injection Molding Machine with Servo Motor70 Ton Bakelite Injection Molding Machine170 Ton Energy Saving Plastic Injection Molding Machine100ton Horizontal Standard Injection Moulding MachineTwo Colors Automatic Injection Moulding Machine for Hand ShankHK 500t Energy Saving Injection Molding MachineXw128t Servo Motor Plastic Injection Molding Machine PriceHt-30 Vertical Hydraulic Injection Molding Machine for PlugHl-125g Vertical Injection Molding Machine with Servo ControlHl-300g Vertical Injection Molding Machinery for Shoe Sole1100 Ton Plastic Injection Molding Machine Price with High SpeedHigh Speed Injection Molding Plastic Machine (wmk-400)500 Ton Plastic Injection Machine (WMK-530)400t Pet Preform Energy Saving Plastic Injection Molding Machine (WMK-400)170 Ton Plastic Injection Molding Machine