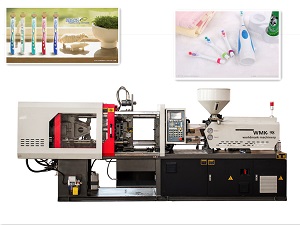

Cheap Plastic Injection Molding Machine for Plastic Product with Servo Motor &ISO9001&SGS&CE Certification Item Wmk-220

Basic Info

Model No.: WMK-220

Product Description

Model NO.: WMK-220 Structure: Horizontal Plasticizing Way: Screw Type Automation: Automatic Certification: CE, ISO9001:2008, SGS Injection Weight: 347gt428gt518g Toggle Stroke: 500mm Machine Dimension(L*W*H): 5.3*1.5*1.95m Pump Motor Power: 22kw Heater Power: 14.25kw Specification: ISO9001 HS Code: 84771010 Type: Preform Injection Plastic Type: Thermoplastic Clamping Way: Hydraulic & Mechanical Computerized: Computerized Clamp Force: 2200kn Injection Rate: 170g/St210g/St254G/S Ejector Stroke: 150mm Machine Weight: 6.9t Machine Dimensions: 5.3X1.5X1.95cm Trademark: WORLDMARK Origin: Jiangsu China Reliable plastic injection machine with servo motor, equiped with servo motor, closed loop control for pressure and flow. Low noise, high precision and energy saving. We design, manuafcture and supply our own brand . with clamping force ranged from 600kn to 16800kn, injection weight from 80g to 11000g, and can provide custom-built machine.

Inject all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, pomponents for automotive, household, eletronics, telecommunication, etc

Advantages:

Control part:

1. It adopts imported computer for plastic injection machine, with large screen. High definiyion crystal display and human-computer interface in different languages. Through CPU independent control and individual treatment. It has raised the running speed of thr control system and alarming of successive oil temperature, thus I, proving the operating speed of the machine.

2. Closed loop temperature control system to ensure the accuracy and reliability of the barrel temperature. The functions of cold proof boot, alarming and parameter memory for the molding, with password protection. The injection and switch are controlled by imported ruler.

Injection part:

1. The excellent chrome, molybdenum and aluminum alloy screw and barrel have undergone the nitrilizing process, applicable to various plastic materials.

2. The injection cylinder(258T advanced) is parallel or balance for both sides of the barrel, so as to ensure the non-deviation of thr nozzle, good sealing and non-leadage. It is equipped with double guide pillar supporting system which can inject under multifarious pressure at various speeds. It also uses one-stop hydraulic pre-injection device.

Hydralic part:

It adopts the imported top quality hydraulic components, proportional control for pressure and flow.

Mouding-adjusment part:

Mold is adjusted by gear controlled by oil motor, the mold can be adjusted automatically in accordance with the setting pressure, which is both convenient and reliable.

Mold part:

1. Five fulcrum crankshaft structure, the mold and bracket structure together, with good rigidity and high-fitting precision, adopting the computerized optimized design. The mold employs finite element analysis, with double pulling and inserting device.

2. Perfroms thefunctions of super sensitive low pressure protection. The mechnical hydraulic and electrical protection have the human safety. The dismounable fill-out hopper can be installed conveniently and automatically. The moveable platen adopts a fixed durable vertical brace that is adjustable. With little friction and balanced dependable moving. Clamp opening is synchro with ejection

Contact us if you need more details on Plastic Injection Molding. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Machine、Injection Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Inject all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, pomponents for automotive, household, eletronics, telecommunication, etc

Advantages:

Control part:

1. It adopts imported computer for plastic injection machine, with large screen. High definiyion crystal display and human-computer interface in different languages. Through CPU independent control and individual treatment. It has raised the running speed of thr control system and alarming of successive oil temperature, thus I, proving the operating speed of the machine.

2. Closed loop temperature control system to ensure the accuracy and reliability of the barrel temperature. The functions of cold proof boot, alarming and parameter memory for the molding, with password protection. The injection and switch are controlled by imported ruler.

Injection part:

1. The excellent chrome, molybdenum and aluminum alloy screw and barrel have undergone the nitrilizing process, applicable to various plastic materials.

2. The injection cylinder(258T advanced) is parallel or balance for both sides of the barrel, so as to ensure the non-deviation of thr nozzle, good sealing and non-leadage. It is equipped with double guide pillar supporting system which can inject under multifarious pressure at various speeds. It also uses one-stop hydraulic pre-injection device.

Hydralic part:

It adopts the imported top quality hydraulic components, proportional control for pressure and flow.

Mouding-adjusment part:

Mold is adjusted by gear controlled by oil motor, the mold can be adjusted automatically in accordance with the setting pressure, which is both convenient and reliable.

Mold part:

1. Five fulcrum crankshaft structure, the mold and bracket structure together, with good rigidity and high-fitting precision, adopting the computerized optimized design. The mold employs finite element analysis, with double pulling and inserting device.

2. Perfroms thefunctions of super sensitive low pressure protection. The mechnical hydraulic and electrical protection have the human safety. The dismounable fill-out hopper can be installed conveniently and automatically. The moveable platen adopts a fixed durable vertical brace that is adjustable. With little friction and balanced dependable moving. Clamp opening is synchro with ejection

| INJECTION UNIT | Unit | WMK-220 | |||

| A | B | C | |||

| Screw Diameter | Mm | 45 | 50 | 55 | |

| Screw L/D Ratio | L/D | 22.2 | 20 | 18.2 | |

| Short Size | Cm3 | 381 | 471 | 569 | |

| Injection weight | G | 347g | 428g | 518g | |

| oz | 12.2 | 15.1 | 18.2 | ||

| Injection Rate | g/s | 170g/s | 210g/s | 254g/s | |

| Plasticizing capacity | g/s | 19 | 23.2 | 28.7 | |

| Injection Pressure | Mpa | 229 | 186 | 154 | |

| Screw Speed | Rpm | 0-190 | |||

| Injection Stroke | mm | 240 | |||

| CLAMPING UNIT | Clamp Force | KN | 2200 | ||

| Space Between Tie Bars | mm | 510*510 | |||

| Toggle Stroke | mm | 500 | |||

| Max. Mold Height | mm | 530 | |||

| Min. Mold Height | mm | 200 | |||

| Ejector Stroke | mm | 150 | |||

| Ejector Tonnage | KN | 62 | |||

| Ejector Number | P | 5 | |||

| Others | Max. pump Pressure | Mpa | 16 | ||

| Pump motor powder | Kw | 18.5 | |||

| Heater Power | Kw | 14.25 | |||

| Machine Dimension(L*W*H) | M | 5.3*1.5*1.95 | |||

| Machine Weight | T | 6.9 | |||

| Oil Tank Capacity | L | 380 | |||

| Hopper Volume | Kg | 50 | |||

Contact us if you need more details on Plastic Injection Molding. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Machine、Injection Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Servo Motor Molding Injection Machine

Premium Related Products

Other Products

Hot Products

170ton High Synchronized Injection Molding Machine100 Ton Bakelite Injection Molding Machine with Servo Motor70 Ton Bakelite Injection Molding Machine170 Ton Energy Saving Plastic Injection Molding Machine100ton Horizontal Standard Injection Moulding MachineTwo Colors Automatic Injection Moulding Machine for Hand ShankHK 500t Energy Saving Injection Molding MachineXw128t Servo Motor Plastic Injection Molding Machine PriceHt-30 Vertical Hydraulic Injection Molding Machine for PlugHl-125g Vertical Injection Molding Machine with Servo ControlHl-300g Vertical Injection Molding Machinery for Shoe Sole1100 Ton Plastic Injection Molding Machine Price with High SpeedHigh Speed Injection Molding Plastic Machine (wmk-400)500 Ton Plastic Injection Machine (WMK-530)400t Pet Preform Energy Saving Plastic Injection Molding Machine (WMK-400)170 Ton Plastic Injection Molding Machine