Plastic injection molding machine

Basic Info

Model No.: QZ-002

Product Description

Brief Introduce

Plastic injection molding equipment consists of plasticizing system ,injection system ,the clamping system and transmission system. Our company has been applying die casting technologies to injection molding machines for many years,like in mechanical ,hydraulic ,electric control ,etc for comprehensive improvement perfect combination of dynamic pressure casting and speed.

In order to improve the stability of syringe production ,we specially add infrared heating coil to Standard Injection Molding Machine .In addition ,we recommend adding servo motor system ,although the servo motor will increase the cost of Injection Molding Machine ,servo motor system has the advantages of energy saving ,in a long term production ,it is more economic ,so nowadays more and more companies choose servo motor system .

Advantage :

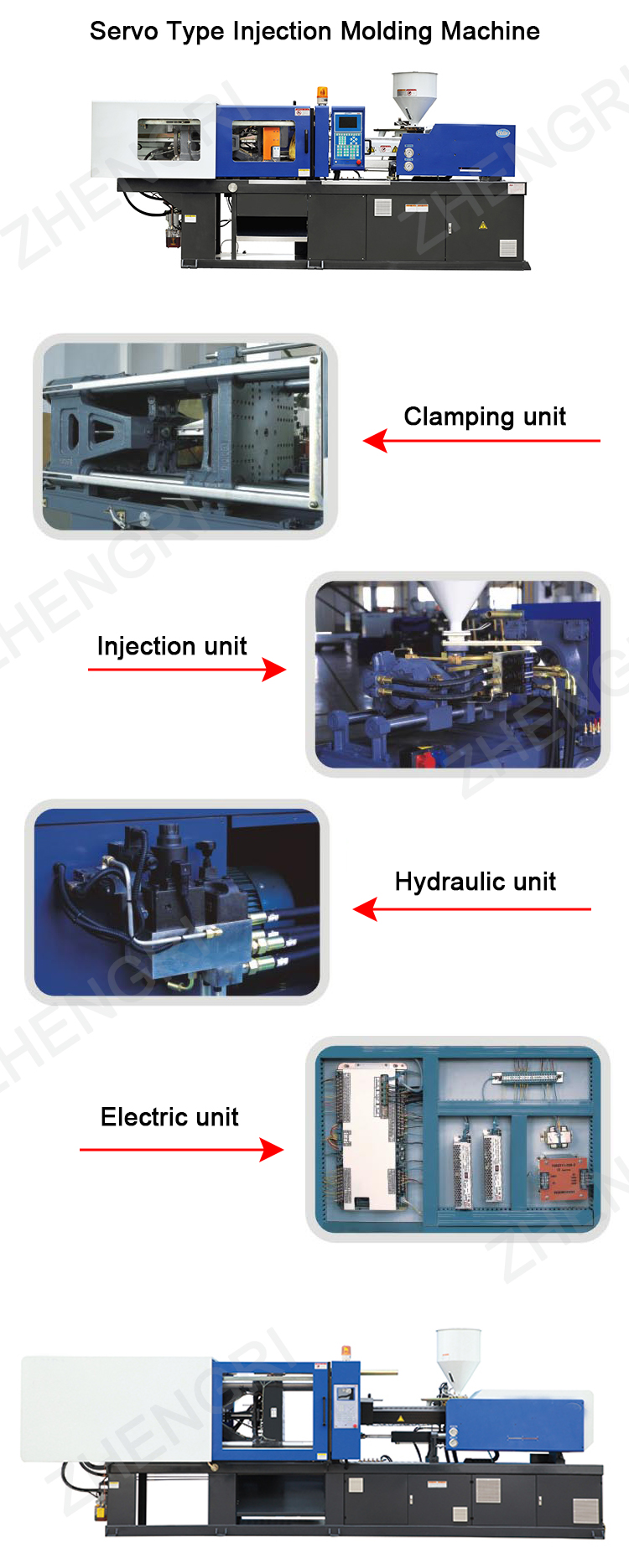

1. Clamping Unit

Reliable 5-pint twin-toggle locking mechanism; Platens are designed under Finite Element Analysis;

High speed clamping is stable while low pressure protection is accurate; Automatic lubrication system;

2. Injection Unit

Double-cylinder balance injection system; Shot weight is precisely controlled by transducer;

Using hydraulic motor to carry out variable speed.

3. Hydraulic Unit

Domestic high-tech divided hydraulic system; Hydraulic safety device; Imported high quality

hydraulic components are applied.

4. Electric Unit

Special controller for Plastic Injection Molding Machine; All the main components are imported from famous company, for example: TE(France), Gefran(Italy),etc.

Technical Paramete

| ITEM | UNIT | DATA | |||

| Injection | Screw Diameter | mm | 45 | 50 | 55 |

| Screw L/D Ratio | L/D | 23.1 | 20.6 | 18.7 | |

| Injection Volume | cm3 | 374 | 461 | 558 | |

| Shot Weight | g | 340 | 420 | 508 | |

| Injection Pressure | Mpa | 210 | 170 | 141 | |

| Clamping | Clamping Force | KN | 2080 | ||

| Opening Stroke | mm | 475 | |||

| Mould Thickness(Min-Max) | mm | 200-520 | |||

| Space Between Tie-Bars | mm | 515×515 | |||

| Ejector Force | KN | 62 | |||

| Ejector Stroke | mm | 165 | |||

| General | Motor Power | KW | 18.5 | ||

| Heater | KW | 16 | |||

| Pump Pressure | Mpa | 16 | |||

| Machine Dimension | m | 5.7×1.4×2.3 | |||

| Machine Weight | T | 6.6 | |||

| Mould Orientation Ring Diameter | mm | Φ160 | |||

| Nozzle Radius | mm | SR15 | |||

Zhengri Technology Co., Ltd was established as a recognized direct manufacturer and exporter in the year 1992. Specializing in all kinds of syringe and infusion set production equipments and production solution. Including Various Syringe Moulds, Infusion set Moulds, Injection Molding Machine Syringe Assembly Machine, Infusion Set Assembly Machine, Syringe Printing Machine, Packaging Machine and eto sterilization machine etc. With our commitment to quality, trust, reasonable price, exceptional after service and overseas customers' loyalty, many products are selected by famous enterprises in our long-term cooperation. So far, we've occupied over 80% China local market, exported to 38 countries including USA, Russia, Vietnam, Turkey, Egypt, India, Indonesia, Chile, Argentia etc. We are looking forward to the future cooperating with you if our products can sincerely impress you.

Pre-sales service:

1- Inquiry and consulting support

2- View our factory

After-sales service

1- Traning how to instal the machine, training how to use the machine

2- Engineers available to service machinery overseas.

3- 1 year free warranty( caused by quality problems),from the machine arrived at buyer's factory.

4- Lifetime maintenance and life time spare parts supply.

Our Advantages:

1. One-stop service: providing a complete range of equipment, material or technical services that customer might require for syringe production.

2. Our machine is of high efficiency and stability. Its technology and performance can reach international advanced level.

3. 20-year experience in designing, researching & developing, manufacturing the syringe equipment.

4. Professional sales team, providing 7x 24 hours service.

5. Overseas after-sales service, skilled engineers will go to install and debug the machine at buyer`s location.

6. Production manager's theoretical and practical training solution, or headhunting service.

Product Categories : Injection Molding Machine