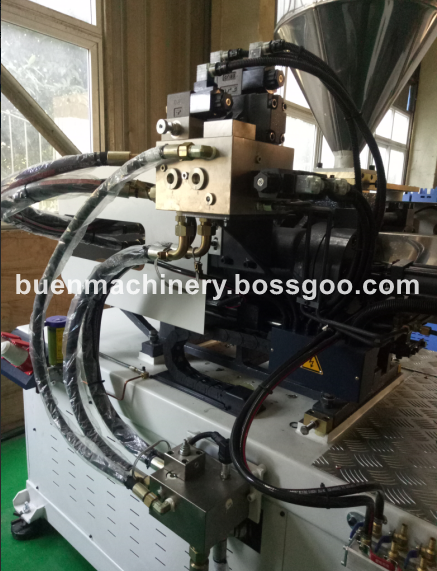

Bakelite injection molding machine 110ton

Basic Info

Model No.: BN-110

Product Description

Bakelite Injection Molding Machine 110ton

Plastic Injection Molding Machine mould clamping unit Optimum designed double-toggle five-joint clamping machinery has functions such as large open stroke,efficient and reliable movement.Multi-eject functions with pressure,speed,position and delay time adjustable are suitable for various molding conditions.In addition,we can deploy multi-servo moulding device according to the requirement of the user.

Clamping system:

-We adopt five fulctum hyperbolic elbow clamping mechnical which can tansfer power effectively and ensure the prcess of high speed response

-Low pressure mold protection system

-Tie bar adopts surface hard chromium plating processing

-Mould platen bottom support use copper material which can protect steel belt

-Automatic centerial lubricarion system which is easy for after service

Injection system:

-Optimization design of the injection unit to provide higher accuracy,ensure the higher stability

-Injection parts adopt double guide tie bars which improve inject technology

-Injection,holding pressure closed-loop control and precision back pressure control

-Cylinder temperature time monitoring to ensure high quality molding requirements.

Electric system:

-The advanced injection plastic machine computer work stable and accurate

-Intelligent method of defects in the course of injection process parameters

-It can save more than one hundred program

-It is equipped with mechanical arm eletrical interface which can be used to match the special mechanical arms for the injection robot.

Hydraulic system:

-Dual proportion load induction oil circuit is used to get steady operation,energy consumption variable with load and energy saving

-The oil box volume is large and the cooling system is arranged properly, it can reduc the oil efficiently

-High function oil pump,liquid motor, seal element can snsure low noise and zero penetration.

-All adopt international well-know hydraulic components

Technical parameters:

| BN-110 | ||||

| INJECTION PART PARTE INYECCIÓN | UNIT | A | B | C |

| Screw diameter Diámetro del tornillo | mm | 34 | 36 | 40 |

| Screw L/D ratio Tasa L/D del tornillo | L/D | 23.1 | 21.8 | 19.6 |

| Shot volume Volumen de Inyección | cm3 | 167 | 188 | 232 |

| Injection weight(PS) Peso de la inyección | g | 153 | 171 | 211 |

| oz | 5.39 | 6.04 | 7.46 | |

| Injection rate Tasa de inyección | cm3/ s | 84.3 | 94.5 | 116.7 |

| Injection pressure Presión de inyección | Mpa | 206 | 183 | 149 |

| Screw speed Velocidad del tornillo | rpm | 210 | ||

| CLAMPING PART PARTE DE CIERRE | ||||

| Clamping force Fuerza de cierre | kN | 1100 | ||

| Opening stroke Apertura | mm | 345 | ||

| Space between tie bars Espacio entre barras | mm | 370×370 | ||

| Mould thickness Espesor de molde | mm | 150~380 | ||

| Ejector stroke Carrera del expulsor | mm | 100 | ||

| Ejector force Fuerza del expulsor | kN | 33 | ||

| Others Otros | ||||

| Oil pump pressure Presión de la bomba de aceite | Mpa | 16 | ||

| Oil pump motor power Potencia del motor de la bomba de aceite | kW | 13 | ||

| Heater power Potencia del calefactor | kW | 7.5 | ||

| Machine dimension Dimensión de la máquina | m | 4.3×1.2×1.75 | ||

| Oil tank capacity Capacidad del tanque de aceite | L | 170 | ||

| Machine Weight Peso de la máquina | t | 3.1 | ||

Processing photos:

Welcome for your inquiry.

Product Categories : Bakelite Injection Molding Machine